I pulled the seats out and replaced the carpet and floor mats. About 20 years ago, I pulled a ratty console and tilt column out

Tag: interior

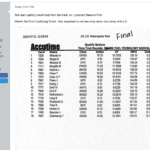

The Screamin’ Woody Heads To The Track

Screamin’ Woody Finish Interior The door cards on the Texas Whale were cardboard with black and gray carpet glued on. For The Screamin’ Woody, I