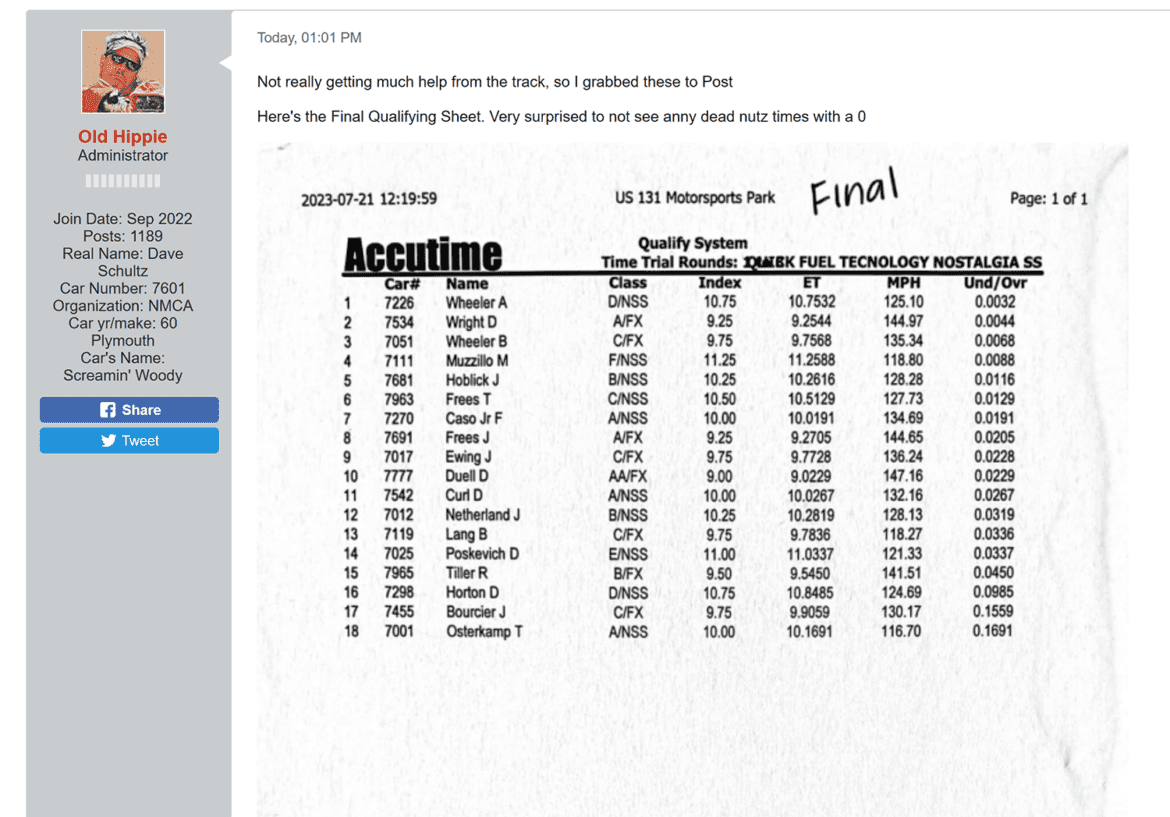

In the NSSRacing forums (https://nssracing.com/forums) there is a discussion with updates on the NMCA race going on in Martin, Michigan. The entire forum is set

Category: Drag Racing

Monster Mopar Weekend 2004

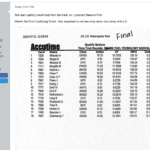

I took these photos 19 years ago with a brand new 1mp digital camera, so the resolution kinda sucks. Many off the NSS cars and

Time to Upgrade Your Door Mat

20% Off For 4th of July

Far Better Than a Facebook Group for Racers

When you post to a group, it is just thrown into a pile of first in and first out of all uncategorized posts. In the

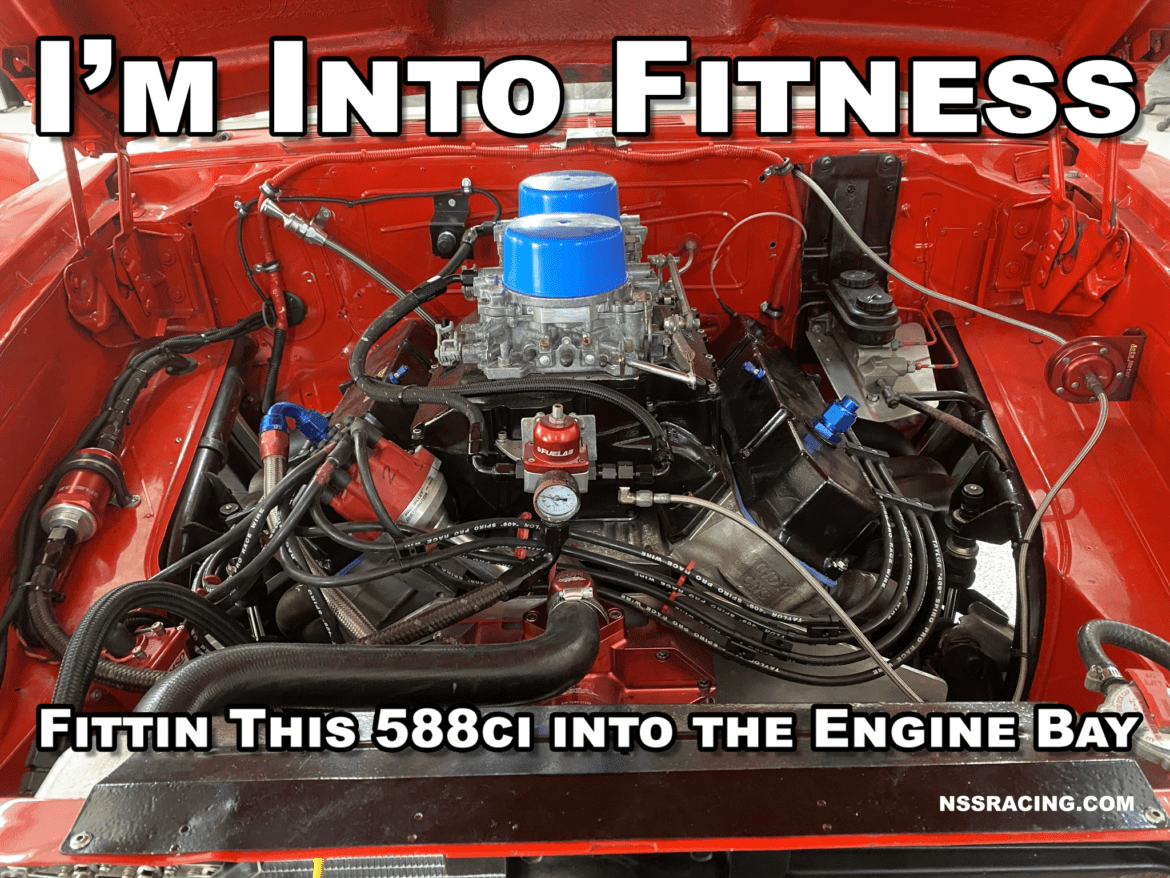

The Vitamin C in 1989

I bought the 63 Plymouth drag car known as the Vitamin C in in 2008. The original builder and owner was John Zimmerman from New

Your First Time Racing at a Drag Strip

Drag Racing 101 Dave Schultz April 20, 2011 Have you ever hammered your car on the highway, or race someone up to the next stop

I Wrecked the Vitamin C in Rockingham

So here’s the video of my wreck. It was a confluence of two big problems. The first is the brakes. The front brakes are Aerospace

I’m Not as Unlucky as Many Think

I have had more than a couple of people telling my luck sucks. While I certainly feel that way sometimes, Bill Hugill said it best.

DRAG PAK #42 FOR SALE

This 2009 Dodge Challenger Drag Pak is as picked up from the factory. In 2009, “Connected Racers” applied to be able to buy the 100

How I Spent My Spring Break in Florida

By Dave Schultz The below is a couple of frames from a video of my wreck last Friday at Orlando Speed World. I’m typically, a

Wrecked the Texas Thug

On my third Time Trial pass, the thick rubber gasket on a Baldwin B2 oil filter push out after my launch. Oil got under the

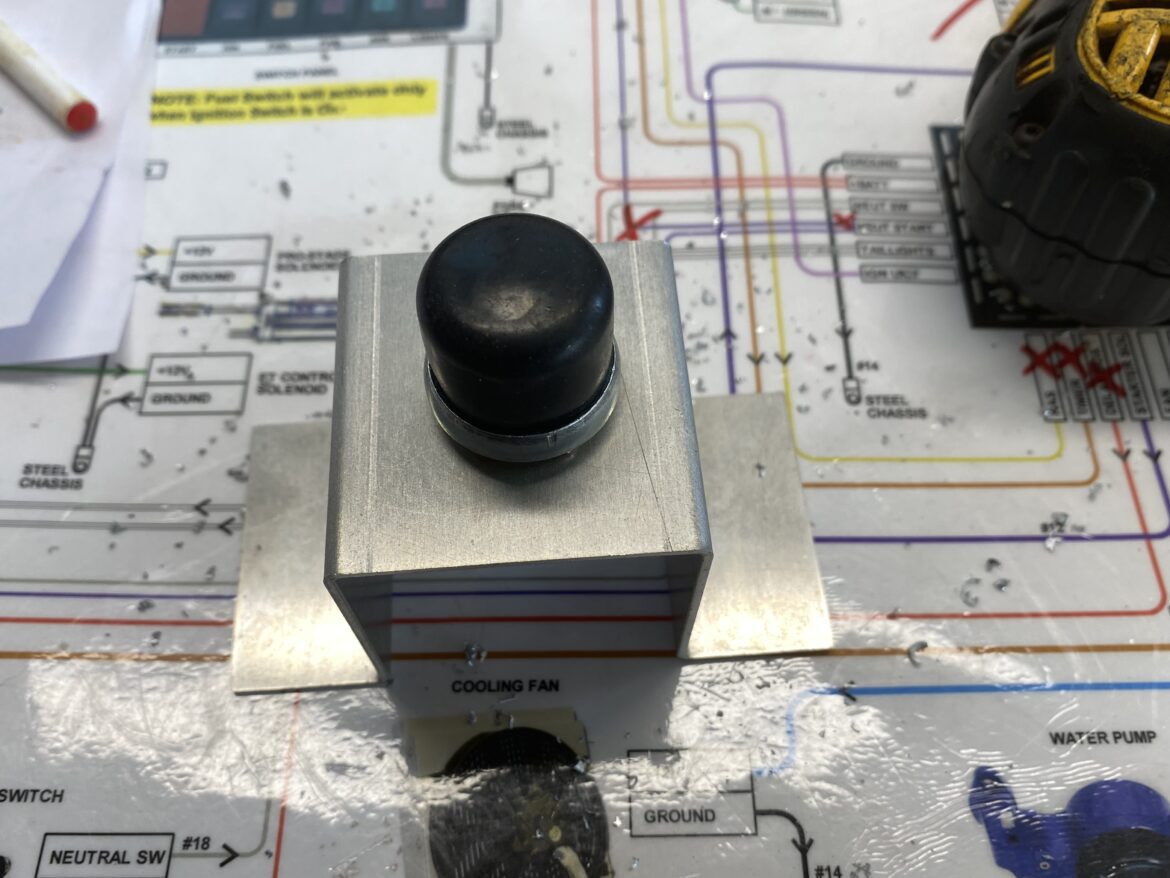

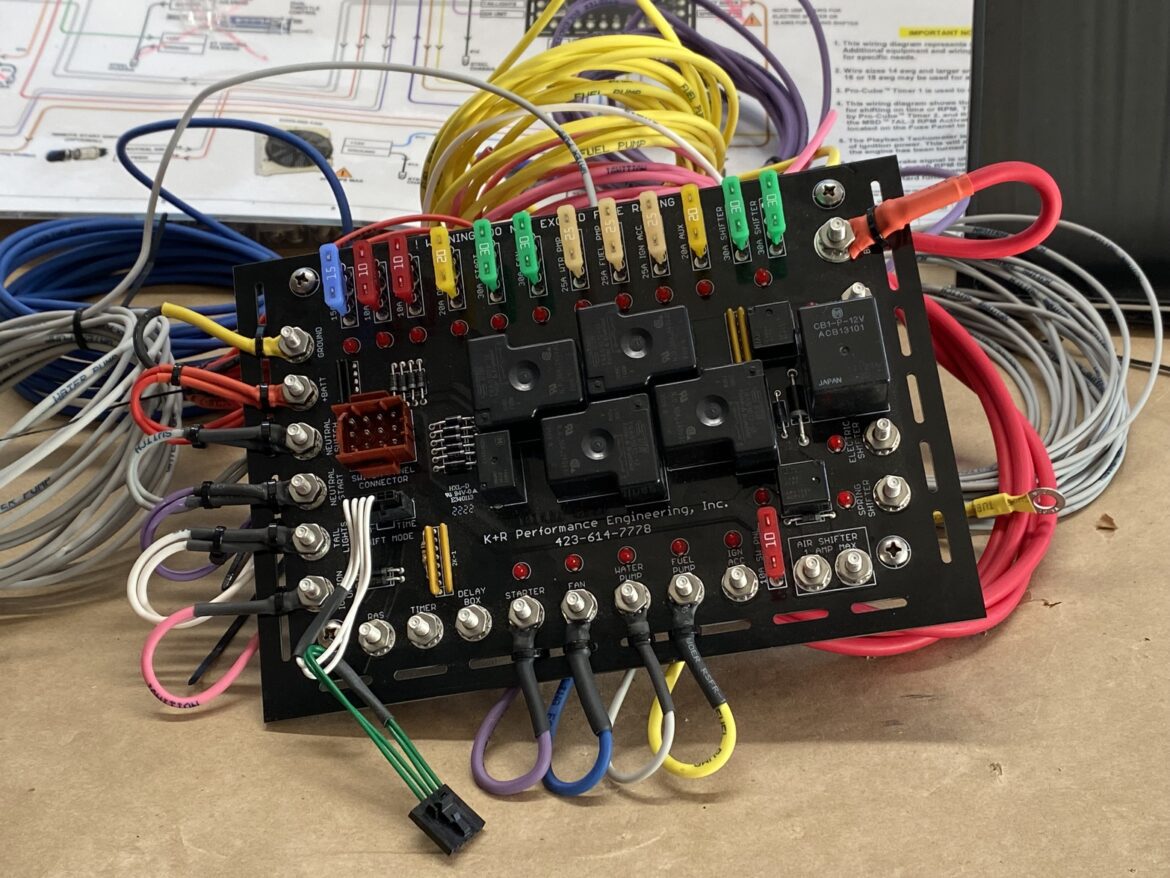

Wagon’s Rewiring is About 90% Done

A little photo drop of where I’m at. What I have left is to run two 12V (actually 16v as I run two 16v batteries

Wiring the Screamin’ Woody – Interior

To this point, I have: Today, I started by removing the starter relay, as all of the relays are on the circuit board. That was

Race Car Wiring – From Bench to Car

With the bench portion of the wiring up the circuit board completed, the board and stringing the various bundles of wires to their destination begin

Rewiring the Screamin’ Woody

One of the weak points of the wagon was the wiring. It was a combination of an 8-circuit Painless panel spliced into existing wiring from

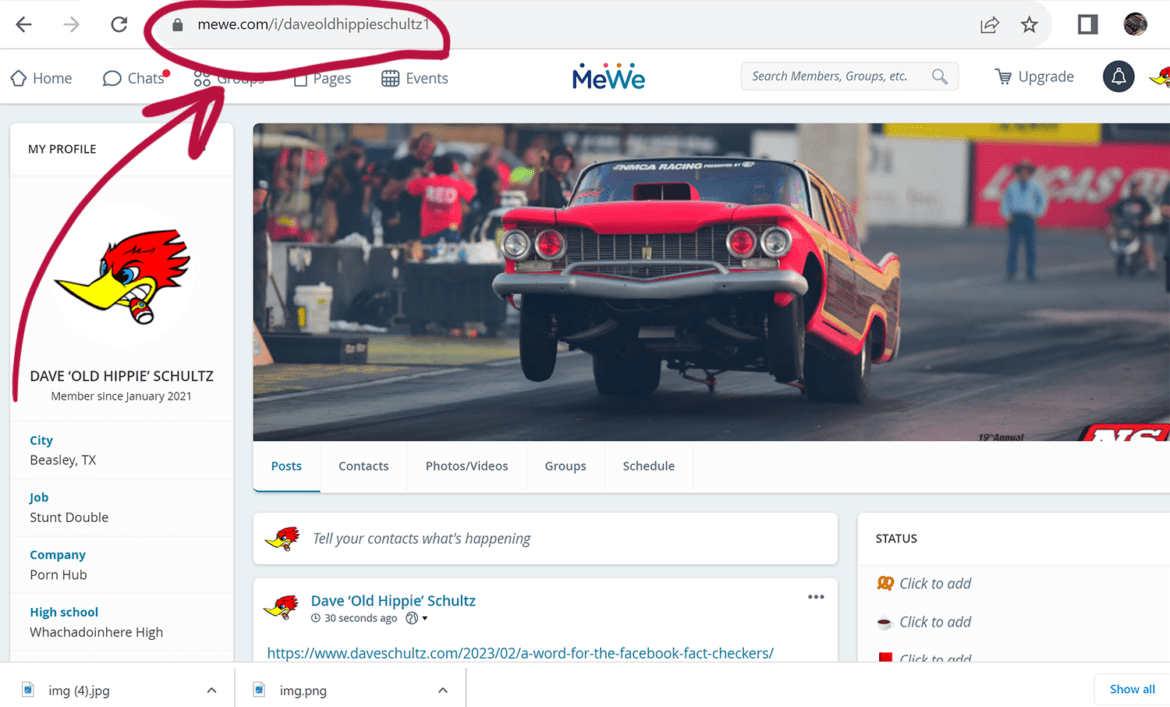

You Won’t Find Me on Facebook

However, I can be found on mewe.